Arrestor Hook: The Ultimate Guide To Safety And Efficiency

Have you ever heard of an arrestor hook? Well, if you haven’t, it’s time to dive into the world of safety tools that keep things from falling off where they shouldn’t. An arrestor hook is one of those unsung heroes in industries like construction, mining, and even maritime. Think of it as the guy who’s got your back when gravity decides to play tricks on heavy equipment.

Now, before we jump into the nitty-gritty, let’s talk about why this little piece of hardware matters so much. Arrestor hooks are not just random metal pieces; they’re precision-engineered tools designed to prevent accidents. Imagine working at heights or handling massive loads—these hooks are what stand between you and disaster. They’re kind of a big deal.

In this article, we’ll break down everything you need to know about arrestor hooks. From their functions to how they’re used in different industries, we’ve got you covered. So buckle up, because we’re about to take a deep dive into the world of safety engineering and see why arrestor hooks are more than just a fancy name.

- Letoya Luckett Young The Journey Of Destinys Child Superstar

- Stream Terrifier 3 For Free Your Ultimate Guide To Unleashing The Horror

What Exactly Is an Arrestor Hook?

Alright, let’s start with the basics. An arrestor hook is essentially a safety device used to secure loads during lifting operations. It’s designed to lock into place automatically, preventing the load from slipping or falling. Think of it as a safety net for heavy-duty equipment. These hooks come in various shapes and sizes, but their primary function remains the same: to keep things secure.

Here’s the cool part—arrestor hooks are engineered with fail-safes. If something goes wrong, like a sudden drop in tension, the hook automatically locks itself. This feature makes them indispensable in industries where safety is paramount. Without these hooks, lifting operations would be a lot riskier than they already are.

Why Are Arrestor Hooks Important?

Let’s talk about why arrestor hooks are such a big deal. In industries like construction and mining, safety is not just a buzzword—it’s a necessity. Arrestor hooks play a crucial role in preventing accidents and ensuring that heavy loads are handled with care. They reduce the risk of dropped objects, which can cause serious injuries or even fatalities.

- Does Instagram Support 4k The Ultimate Guide To Uploading And Sharing Stunning Videos

- Hd Hub The Ultimate Guide To Highdefinition Streaming And Entertainment

Here’s a quick rundown of why arrestor hooks matter:

- Prevent accidents by securing loads effectively.

- Reduce the risk of dropped objects in high-risk environments.

- Enhance safety protocols in industries like construction and mining.

- Provide peace of mind for workers handling heavy equipment.

When it comes to safety, you can’t afford to cut corners. That’s where arrestor hooks come in—they’re the unsung heroes of the workplace.

How Do Arrestor Hooks Work?

Now that we’ve established why arrestor hooks are important, let’s take a closer look at how they work. These hooks are designed with a clever mechanism that allows them to lock automatically when under load. The locking mechanism ensures that the hook stays secure, even if there’s a sudden change in tension.

Here’s a step-by-step breakdown of how arrestor hooks operate:

- Initial Engagement: The hook is attached to the load, and the locking mechanism engages.

- Load Application: As the load is lifted, the hook remains securely locked in place.

- Automatic Locking: If the load shifts or tension changes, the hook automatically adjusts to maintain its grip.

- Safe Release: Once the load is safely positioned, the hook can be manually released.

This automatic locking feature is what sets arrestor hooks apart from other types of hooks. It’s a game-changer in terms of safety and reliability.

Types of Arrestor Hooks

Not all arrestor hooks are created equal. Depending on the application, there are different types of arrestor hooks available. Here’s a quick overview of the most common types:

Swivel Hooks

Swivel hooks are designed to rotate freely, making them ideal for applications where the load needs to move without restriction. They’re commonly used in rigging and lifting operations where flexibility is key.

Quick-Release Hooks

Quick-release hooks, as the name suggests, allow for easy detachment of the load. They’re perfect for situations where time is of the essence, such as emergency rescues or rapid deployment scenarios.

Self-Locking Hooks

Self-locking hooks are the workhorses of the arrestor hook family. They automatically lock into place when under load, providing maximum security. These hooks are widely used in construction and mining industries.

Choosing the right type of arrestor hook depends on the specific needs of your operation. Whether you need flexibility, speed, or security, there’s an arrestor hook out there that fits the bill.

Applications of Arrestor Hooks

Arrestor hooks are versatile tools that find applications in a wide range of industries. Here are some of the most common uses:

Construction

In construction, arrestor hooks are used to lift and secure heavy materials like steel beams and concrete slabs. They ensure that these materials are handled safely, reducing the risk of accidents on the job site.

Mining

Mining operations often involve lifting heavy equipment and materials. Arrestor hooks are crucial in these environments, where safety and reliability are top priorities.

Maritime

On ships and offshore platforms, arrestor hooks are used to secure cargo and equipment. They help prevent accidents caused by rough seas or sudden movements.

No matter the industry, arrestor hooks play a vital role in ensuring safety and efficiency.

Selecting the Right Arrestor Hook

Choosing the right arrestor hook for your needs can be a daunting task. With so many options available, it’s important to consider factors like load capacity, material, and application. Here are some tips to help you make the right choice:

- Load Capacity: Make sure the hook you choose can handle the weight of the load you’ll be lifting.

- Material: Stainless steel hooks are ideal for corrosive environments, while forged steel hooks offer superior strength.

- Application: Consider the specific requirements of your operation when selecting a hook.

Taking the time to choose the right arrestor hook can save you a lot of headaches down the road.

Maintenance and Care

Like any piece of equipment, arrestor hooks require regular maintenance to ensure they function properly. Here are some tips for keeping your hooks in top condition:

- Inspection: Regularly inspect hooks for signs of wear and tear, such as cracks or deformation.

- Cleaning: Keep hooks clean and free of debris to prevent rust and corrosion.

- Lubrication: Apply lubricant to moving parts to ensure smooth operation.

Proper maintenance not only extends the life of your hooks but also ensures their safety and reliability.

Safety Standards and Regulations

When it comes to arrestor hooks, compliance with safety standards and regulations is crucial. Different countries and industries have their own set of guidelines, so it’s important to be aware of what applies to your operation. Here are some key standards to keep in mind:

- OSHA: In the United States, the Occupational Safety and Health Administration (OSHA) sets standards for the use of lifting equipment.

- ISO: The International Organization for Standardization (ISO) provides guidelines for the design and testing of lifting hooks.

Staying up-to-date with these standards ensures that your arrestor hooks meet the highest safety requirements.

Future Developments in Arrestor Hook Technology

As technology continues to evolve, so do the tools we use for safety. Arrestor hooks are no exception. Engineers are constantly working on new designs and materials to improve the performance and reliability of these hooks. Here are some exciting developments to look out for:

- Smart Hooks: Equipped with sensors, these hooks can provide real-time data on load conditions and automatically adjust to ensure safety.

- New Materials: Advances in materials science are leading to the development of lighter, stronger hooks that offer superior performance.

The future of arrestor hooks looks bright, with innovations that promise to make them even safer and more efficient.

Conclusion

In conclusion, arrestor hooks are indispensable tools in industries where safety is a top priority. From their automatic locking mechanisms to their versatility in various applications, these hooks offer peace of mind to workers handling heavy loads. By understanding their functions, selecting the right type for your needs, and maintaining them properly, you can ensure that your operations run smoothly and safely.

We encourage you to share this article with your colleagues and friends who might benefit from learning more about arrestor hooks. And don’t forget to check out our other articles for more insights into safety engineering and industrial tools. Stay safe out there!

Table of Contents

- What Exactly Is an Arrestor Hook?

- Why Are Arrestor Hooks Important?

- How Do Arrestor Hooks Work?

- Types of Arrestor Hooks

- Applications of Arrestor Hooks

- Selecting the Right Arrestor Hook

- Maintenance and Care

- Safety Standards and Regulations

- Future Developments in Arrestor Hook Technology

- Conclusion

- Download Hd Movies Your Ultimate Guide To Highquality Entertainment

- Nihil Definition Understanding The Concept That Shapes Modern Thought

6 Aircraft Arrestor Hook Images, Stock Photos, 3D objects, & Vectors

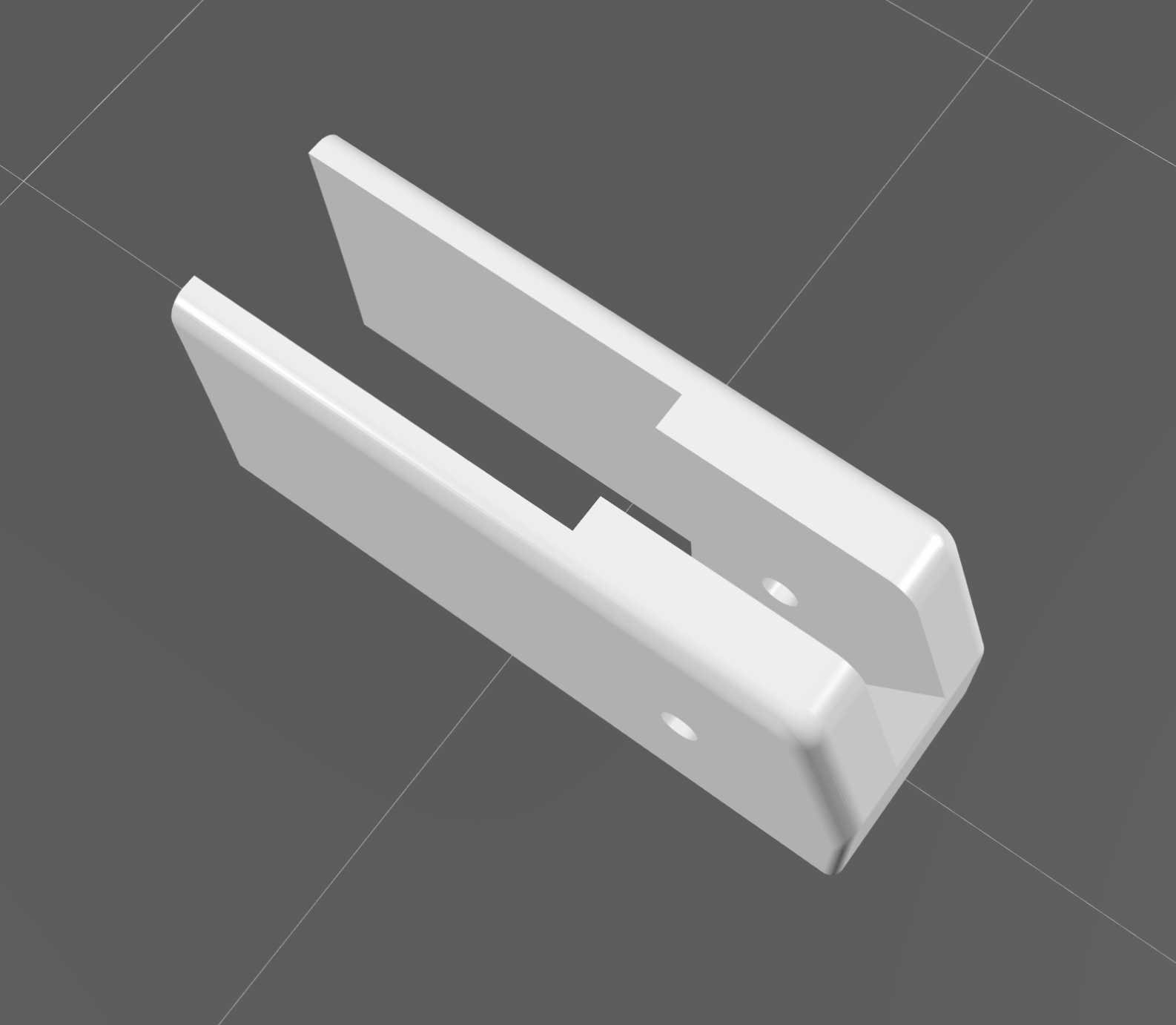

Phantom F4 Arrestor hook bracket.stl SemiScale Parkjets

Phantom F4 Arrestor hook.stl SemiScale Parkjets